Dispose of the straw in the two sessions this year has become the focus of discussion!

Wheat, straw, reed, etc. are common known plant straw fiber, most of the daily life is burned or returned to the field, has not been really used up. In recent years, the National Development and Reform Commission, the Ministry of Agriculture, the Ministry of Finance and other ministries issued a document to encourage the comprehensive utilization of plant straw to improve the use of straw value, reduce the burning of the atmosphere on the atmosphere ... ... ... ... so On the comprehensive utilization of straw technology achievements continue to emerge, such as plant straw processing oil, plant straw processing plate, plant straw fiber and resin combined production flower pots, straw fiber power generation, plant straw fiber production molding products, etc., where I focus Introduce the comprehensive utilization of plant stalks in pulp molded products.

Wheat, straw, reed, etc. are common known plant straw fiber, most of the daily life is burned or returned to the field, has not been really used up. In recent years, the National Development and Reform Commission, the Ministry of Agriculture, the Ministry of Finance and other ministries issued a document to encourage the comprehensive utilization of plant straw to improve the use of straw value, reduce the burning of the atmosphere on the atmosphere ... ... ... ... so On the comprehensive utilization of straw technology achievements continue to emerge, such as plant straw processing oil, plant straw processing plate, plant straw fiber and resin combined production flower pots, straw fiber power generation, plant straw fiber production molding products, etc., where I focus Introduce the comprehensive utilization of plant stalks in pulp molded products.The pulp molded product is a three-dimensional papermaking technique that uses straw fiber to break through the slurry and mix it into the mold, molded by piping. Its products are impermeable and impermeable, waterproof and anti-oil, can be refrigerated can be heated to bake, no pollution and degradation characteristics, the straw fiber is 100% use, in addition to a small amount of food-grade waterproof and anti-oil agent, do not add Other chemical ingredients, is a completely from the nature of the environmental protection container! The application of plant straw fiber in pulp molding products is mainly based on the following aspects:

1、food packaging

1、food packaging

Wheat straw lunch box

Mainly the product is a one-time straw environmental tableware, cake tray, etc., for now the food packaging is the most widely used, the largest number of a class, with universal. Disposable straw is a very widely used tableware, can be used in food and beverage, entertainment (such as KTV in full bloom), all kinds of conference centers. With China and the developed countries on the importance of white pollution, also introduced the relevant laws and regulations, and promote the development of straw utensils. In 2011, the world's total consumption of disposable degraded tableware totaled about 68.89 billion; in 2013, the world's total consumption of disposable tableware was about 74.75 billion. From the above data can be seen that this is widely used in the demand for environmentally friendly consumables in the continuous growth, but also has great room for development!

Baking packaging: these products are nearly three years before the popular and developed, replaced the cardboard cake before the cake and the base. Straw fiber cake plate with good hardness, high grade, shape and other characteristics of diversification, with the continuous improvement of baking food grade, straw products in line with the current bakery industry trends. Take the example of China's 1.3 billion population, with an average of 3 million people a day. Each cake is based on five cake dishes, one day is 15 million, a year is 5.5 billion, and the actual data is far greater than this figure Not just have a birthday cake to use straw cake, a variety of party usage may be higher). In addition baking industry profits higher, packaging is also higher than the ordinary tableware products in the value-added products with greater advantages and space.

2, straw industrial packaging (commonly known as paper care) referred to as PMP, which is based on various types of plant straw as raw material, by hydraulic pulping, ingredients and other processes into a certain concentration of slurry, the slurry in a special metal mold adsorption Wet billet products, forming a good wet billet and then dry, hot and plastic from the shape. The main product type to high-end computer box (such as Dell), mobile phone box (Apple, HTC, etc.), razor liner (such as Gillette razor), precision instrument lining, cosmetic case and so on. On the one hand to play the role of earthquake protection, on the other hand but also play the role of beautiful decoration. With the internationalization of electronic products, various countries have also made a request for their packaging to limit or even prohibit the use of foam foam as a product lining to reduce white pollution. In China's exports of industrial packaging, such products can account for about 60% of the share of the market demand, the application to receive a wide range.

3, medical packaging

The use of straw fiber as raw materials made of medical products used in the field, mainly used in hospitals, front of the field of disposable medical products, such as paper pots, paper pots, hand care and so on. The use of such products in general, the one-time can be broken into paper fiber into the hospital sewage system advantages, can definitely avoid cross-pathogenic contamination. With the substantial increase in medical standards, the state of social health care investment, higher health, the use of more convenient disposable medical supplies will be increasingly widely used, which for the development of renewable straw fiber products created Hatching the convenience of the future through the increase will be such new product research and development efforts, straw fiber for the development of the world medical cause to do their own contribution!

4, to promote agricultural straw packaging.

Mainly used in fruit, eggs, agricultural bread packaging straw fiber products, the use of the more common is the egg tray and pots, nursery cups and other products, such products are pollution-free, biodegradable and other characteristics, but also according to the consumer The taste, the fiber dyeing, made of various types of style. China is a big agricultural country, the future development of agriculture will have more national policy support, therefore. As long as seize the opportunity to increase the intensity of new product research and development, straw fiber in the field of agriculture will certainly use their own characteristics.

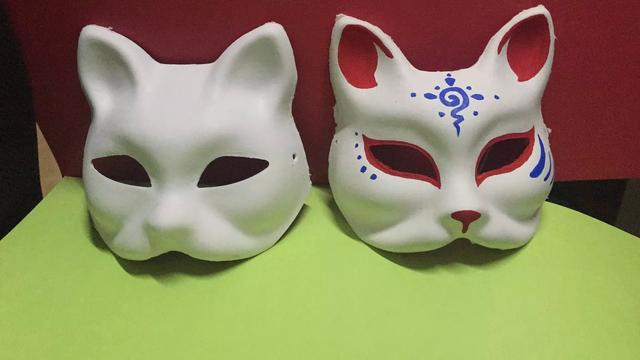

5、entertainment toys.

Mainly in children's face, animal crafts toys, such products for new products, the market is not widely widespread, but is gradually replacing the traditional plastic products, with great room for development. In particular, foreign often open some mask dance, such a one-time mask to carry convenient, low prices, coupled with the use of such festivals such as Halloween, such products have been foreign consumers love.

6, new building materials.

The main types include decorative wall panels, decorative ceilings, high density boards, and lightweight insulation materials.

(1), decorative wall panels, ceilings. Is a straw fiber as raw material by beating, suction filtration, high temperature stereotypes, trimming and other 20 processes to form a new type of interior wall materials.

(2), high density board. MDF is a kind of artificial fiber made of plant fiber, which is excellent in its physical properties, compatible with all the advantages of MDF, widely used in indoor and outdoor decoration, office, high-grade furniture, audio, Interior decoration, but also can be used as computer room anti-static floor, wall panels, security doors, wall panels, partitions and other production materials, it is a good packaging materials! The research and development of high-density fiberboard project will be one of the important development directions of our straw utilization. The research and development of this project is not only to promote the use of straw, but also to improve the performance of straw utilization, which greatly improves the utilization of straw Value-added, while such products market development space is large, can be widely used!

(3), light insulation building materials. Straw wall insulation material is a kind of new energy saving and environmental protection ecological building material with corn stalk as raw material. Because of the renewable use of raw materials, it does not pollute the environment, but also has a wide range of sources, good performance, practicality, low consumption and high yield, light , Easy to fast construction and other characteristics, is regarded as the future of the construction industry indispensable raw materials. At present the market has the existing straw sheet, has formed a multi-standard, multi-purpose, multi-functional product line. For example: light interior wall partitions, bathroom partitions, high insulation wall panels, strong insulation wall panels, insulation panels, strong waterproof roof panels. Because of its production according to map, easy to install and so on, widely used in a variety of frame architecture, gymnasium, plant warehouse, disaster relief housing, hotels, shopping malls and other office buildings. With the progress of science and technology and capital support for the development of wood-based panel industry provides a good condition. Straw board is adapted to this high-tech needs came into being. As the straw board products have a broad application space, and the production cost of the product is low, superior product performance advantages, will lead to the product has a strong market competitiveness. Especially at present, the national natural forest protection project is being implemented, many ordinary particleboard factory will face the contradiction between supply and demand of raw materials, so that its market competitiveness decline. The next decade, the annual demand for straw man-made board will be more than 350 million square meters. Therefore, China's straw sheet production has a wide range of prospects.

Straw plant fiber synthesis is a big issue, but also the development of the times we have made the request to Shandong Walker Environmental Technology Co., Ltd. as the leading team through the development of research in recent years, in the pulp molding application has been great , But there are still low utilization rate, added value is not high and so on, so continue to improve the plant straw fiber technology research and development, strengthen R & D investment, and constantly optimize the innovation of new products to the comprehensive utilization of straw to carry out this issue better! Straw plant fiber in the pulp molding application is also far more than the above aspects, there are more mining and development of space, so environmentalists, researchers only more with the current needs of social development in order to plant straw fiber Comprehensive use to make more achievements!